Notifications

In recent years, the manufacturing industry has witnessed a transformative wave driven by technological advancements. Among these innovations, Artificial Intelligence (AI) video analytics stands out as a potent tool capable of revolutionizing various aspects of manufacturing processes. By harnessing the power of AI to analyze video feeds from factory floors, production lines, and warehouses, manufacturers can achieve significant improvements in efficiency, safety, quality control, and overall operational effectiveness. This essay explores the myriad ways AI video analytics is reshaping the manufacturing landscape and the profound benefits it brings to the industry.

One of the most critical applications of AI video analytics in manufacturing is in quality control. Traditional methods often rely on manual inspection, which can be time-consuming and prone to human error. AI video analytics, on the other hand, can continuously monitor production lines in real-time, identifying defects and anomalies with a level of precision that surpasses human capabilities.

For instance, AI algorithms can be trained to detect surface defects, incorrect assembly, or dimensional inconsistencies in products. By analyzing video footage, the system can flag defective items instantaneously, allowing for immediate corrective action. This not only reduces the likelihood of defective products reaching customers but also minimizes waste and rework costs.

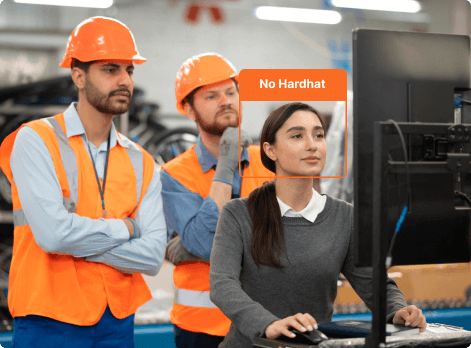

Workplace safety is paramount in the manufacturing industry, where hazardous environments and heavy machinery pose significant risks to workers. AI video analytics can play a crucial role in enhancing safety protocols and ensuring compliance with industry regulations.

AI systems can monitor video feeds to detect unsafe behaviors, such as workers not wearing proper protective equipment, unauthorized personnel entering restricted areas, or the presence of obstacles in walkways. Upon detecting such risks, the system can trigger alerts to supervisors or directly to workers, preventing accidents before they occur. Additionally, AI can assist in maintaining compliance with safety standards by continuously tracking and reporting safety violations, thus fostering a culture of safety within the organization.

Operational efficiency is a key driver of profitability in manufacturing. AI video analytics contributes to this by optimizing various processes on the factory floor. For example, AI can analyze video footage to monitor machine performance and identify patterns that indicate potential failures. By detecting early signs of wear and tear or malfunction, the system can prompt maintenance activities before a breakdown occurs, thereby reducing downtime and extending the lifespan of equipment.

Moreover, AI video analytics can streamline workflow management by tracking the movement of materials and products through the production process. This real-time visibility helps in identifying bottlenecks, optimizing resource allocation, and ensuring that production schedules are adhered to, ultimately leading to improved throughput and reduced lead times.

Effective inventory management is crucial for maintaining production continuity and meeting customer demand. AI video analytics enhances inventory management by providing real-time insights into stock levels and the movement of goods. By monitoring video feeds from warehouses and storage areas, AI can track inventory usage, predict stock shortages, and optimize reordering processes.

In the broader context of supply chain optimization, AI video analytics can be used to monitor the loading and unloading of goods, ensuring that shipments are handled efficiently and accurately. This visibility extends to the entire supply chain, allowing manufacturers to identify and address potential disruptions, improve logistics planning, and maintain a seamless flow of materials and products from suppliers to customers.

AI video analytics also offers significant benefits in workforce management. By analyzing video feeds, AI can track employee activities, monitor productivity levels, and ensure adherence to operational protocols. This data can be used to identify training needs, optimize task assignments, and improve overall labor efficiency.

For instance, AI can identify areas where workers may be experiencing delays or difficulties, enabling supervisors to provide targeted support or training. Additionally, by monitoring break times and shift changes, AI can help ensure that labor regulations are being followed, and that employees are receiving adequate rest, thereby enhancing overall job satisfaction and reducing turnover rates.

Sustainability is an increasingly important consideration for manufacturers, driven by regulatory requirements and growing consumer demand for environmentally responsible products. AI video analytics can contribute to sustainability efforts by monitoring environmental conditions within the manufacturing facility.

For example, AI can analyze video footage to track energy usage, identify leaks or spills, and monitor emissions. By providing real-time data on these factors, manufacturers can take proactive measures to reduce their environmental footprint, improve energy efficiency, and ensure compliance with environmental regulations. This not only supports sustainability goals but can also result in cost savings through more efficient resource utilization.

In the era of Industry 4.0, the ability to quickly adapt to changing market demands and customize products is a significant competitive advantage. AI video analytics supports this flexibility by enabling more agile manufacturing processes. By providing detailed insights into production activities, AI allows manufacturers to rapidly adjust workflows, implement changes, and scale production up or down based on demand.

This capability is particularly valuable in industries with high variability in product types and volumes, such as electronics or automotive manufacturing. With AI video analytics, manufacturers can maintain high levels of efficiency and quality even as they adapt to new product specifications or production requirements.

AI video analytics software is a transformative technology that offers a wide array of benefits for the manufacturing industry. From enhancing quality control and safety to improving operational efficiency and sustainability, AI-driven video analysis provides manufacturers with the tools they need to stay competitive in a rapidly evolving market. By leveraging AI video analytics, manufacturers can achieve greater precision, agility, and insight, leading to more efficient and effective operations. As AI technology continues to advance, its integration into manufacturing processes will undoubtedly drive further innovations and unlock new possibilities for the industry.