Categories

Tags

-

#seo

#web design

#website design

#website designer

#SEO experts

#Web Development

#RoofRepair

#it company

#employee engagement

#property management companies

#eLearning

#IT Services

#Water Damage Restoration

#doctor

#builders

#website development

#IT support

#Cancer

#digital signage

#a healthy divorce

#divorce mediation

#family attorney

#file for divorce

#mediation san diego

#local exhibits

#exhibits company

#trade show booth design

#trade show rentals

#trade show booth

#exhibit design firms

#Beyond Architects

#architect auckland

#architects in auckland

#architect firms auckland

#town planner auckland

#home renovations auckland

#k and r properties

#rental management companies

#cheap houses for rent

#1 bedroom apartment for rent

#garage for rent san diego

#skymedia

#hotel digital signage

#video wall

#touch screen monitor

#led video wall

#hilary hendershott

#financial advisor

#Fiduciary Standard of Care

#Investing Podcast

#finance podcasts

#woman podcast

#Wealth Multiplier Course

#2the rescue llc

#mold remediation company

#mold removal company

#fire damage restoration

#emergency water damage

#grand rapids lock smith

#auto locksmith

#mobile locksmith

#automobile locksmith

#key replacement

#855 lysters

#Jackson Roofing

#Kalamazoo Roofing

#Battle Creek Roofing

#Roof Repair Kalamazoo

#Roofing Companies Kalamazoo Mi

#speaker booking agency

#book a speakers

#Business Speakers

#diversity and inclusion speakers

#Leadership Speakers

#Innovation Speakers

#atlas health best

#chiropractor st louis

#chiropractor winter garden

#atlas speed training winter garden

#st michael chiropractor

#dependable lp gas

#propane gas

#propane gas company

#lp gas west michigan

#residential propane gas

#west michigan propane gas

#home works remodel it

#home improvement company

#roofing company

#remodeling company

#basement remodeling company

#jot and tittle concrete

#ready mix concrete company

#concrete companies

#ready mix concrete companies

#concrete company

#no limit contracting and design

#bathroom remodels

#new home builder

#home addition contractor

#home siding company

#window replacement company

#kitchen remodeling company

#your voice in trial

#Car Accident Attorneys

#Motorcycle Accident Attorney

#Bicycle Accident Attorney

#Slip And Fall Attorneys

#Wrongful Death Fort Myers

#mediation center

#all in one online shopping

#online shopping hub

#Mens Wallet Brands Buy Online

#mens shoes online shopping

#mens online clothing stores

#bath and body works sale

#cruise sd

#San Diego Boat Tours

#Things to do San Diego

#Wedding Packages

#Cruise Party

#San Diego Sightseeing

#sdwhalewatch

#sd whale watch

#whale watching tour agency

#whales in san diego

#bay cruises san diego

#whale watch near me

#dolphin watch

#consultative leadership

#leadership gaps

#talent on demand

#executive hiring

#executive placement firms

#executive recruiters

#Royal Springs

#Spring water melbourne

#Pure Water melbourne

#Drinking water melbourne

#Water chiller melbourne

#roofing contractors

#roof repair

#match and cover

#speakerbookingagency

#bookaspeakers

#BusinessSpeakers

#diversityandinclusionspeakers

#LeadershipSpeakers

#InnovationSpeakers

#Floor Sanding

#Floor Refinishing

#Hardwood Floor Sanding

#sanding and refinishing wood floors

#hardwood floor refinishing

#se construction

#acrylic render

#Melbourne Rendering

#cement rendering

#solid plasterer

#house rendering

#abc floor sanding

#teruke

#Ready to eat food in Nigeria

#Nigerian food

#Nigerian meals

#African restaurants

#Beans porridge

#Jollof rice

#Content Marketing Strategy

#petals of love

#Florists St. Thomas Ontario

#Flower Store St. Thomas Ontario

#Funeral Flowers St. Thomas

#Wedding Flowers St. Thomas

#Get Well Flowers St. Thomas

#trads furniture

#mattresses london ontario

#bedroom furniture london ontario

#furniture store london ontario

#home furniture london ontario

#living room furniture london ontario

#dininig room furniture london ontario

#furniture shop london ontario

#Catering London

#Caterers London

#Business Catering London

#Lunch Catering London

#Catering Companies London

#Funeral Flowers St

#willies cafe and catering

#Lunch Catering London Ontario

#Sandwich Catering London Ontario

#touch screen signage singapore

#touch screen monitor singapore

#digital menu

##hoteldigitalsignagesingapore

##videowallsingapore

##touchscreenmonitorsingapore

##ledvideowallsingapore

#Business Catering London Ontario

#Caterers London Ontario

#Catering London Ontario

#kalamzoo locksmith

#auto car locksmith

#automotive locksmith

#sliding doors

#exterior paint san diego

#san diego house painter

#san diego exterior painting

#painter san diego

#san diego painting company

#painting san diego

#painting company in san diego

#painters san diego

#Keywords--teruke

#laser cutting services

#laser cutting near me

#laser marking engraving

#anti aging clinic san diego

#hormone specialist san diego

#iv therapy san diego

#iv san diego

#drywall contractors

#drywall repair

#lasercut services

#helium leak testing

#laser engraving services

#bioidentical hormones near me

#botox san diego

#prp san diego

#CBD oil for dogs

#CBD oil for anxiety

#CBD benefits for cats

#CBD holistic benefits

#sliding glass doors

#sliding patio doors

##JacksonRoofing

##KalamazooRoofing

##BattleCreekRoofing

##RoofRepairKalamazoo

##RoofingCompaniesKalamazooMi

##propanegaswestmichigan

##propanegascompanyioniacounty

##propanegascompanyrockfordmi

##propanegascompanycaIedoniami

##propanegascompanybyroncentermi

##homeimprovementcompanymishawakain

##roofingcompanyinsouthbendin

##remodelingcompanysouthbendin

##basementremodelingcompanyElkhartin

##readymixconcretecompanyfortmyersfl

##concretecompaniesinsouthwestflorida

##readymixconcretecompaniesnaplesfl

##concretecompanyfortmyersfl

##bathroomremodelsgreenvillenc

##newhomebuildergreenvillenc

##homeadditioncontractorgreenvillenc

##homesidingcompanygreenvillenc

##windowreplacementcompanygreenvillenc

##greenvillenckitchenremodelingcompany

##CarAccidentAttorneysFortMyers

##MotorcycleAccidentAttorneyFortMyers

##BicycleAccidentAttorneyCapeCoralFlorida

##2therescuellc

##waterdamagerestorationcompanygrandrapidsmi

##moldremediationcompanycomstockparkmi

##moldremovalcompanykentwoodmi

##speakerbookingagency

##bookaspeakers

##BusinessSpeakers

##diversityandinclusionspeakers

##LeadershipSpeakers

##InnovationSpeakers

##divorcemediation

##familyattorney

##file fordivorce

##mediationsandiego

##mediationcenter

##FloorSanding

##FloorRefinishing

##HardwoodFloorSanding

##sandingandrefinishingwoodfloors

##hardwoodfloorrefinishing

##exhibitscompany

##tradeshowboothdesign

##tradeshowrentals

##tradeshowbooth

##exhibitdesignfirms

##SanDiegoBoatTours

##ThingstodoSanDiego

##WeddingPackagesSanDiego

##CruiseParty

##SanDiegoSightseeing

##lasercuttingservices

##lasercuttingnearme

##lasermarkingengraving

##lasercutservices

##sdwhalewatch

##whalewatchingtouragency

##whalesinsandiego

##kandrproperties

##propertymanagementcompanies

##rentalmanagementcompanies

##cheaphousesforrent

##1bedroomapartmentforrent

##garageforrentsandiego

#Dental Care in Three Rivers

#Three Rivers Dentist

#Three Rivers MI Dentist

#Dentistry in Three Rivers MI

#buy fresh seafood online

#fresh sea urchin

#abalone for sale

#sashimi at home

#sunset cruise

#renting a yacht

#party boat rental

#private boat charter

#Sboat charter

#perfection clean results

#perfection carpet cleaning

#carpet cleaning peabody

#WHALE WATCHING TOURS

#recent whale sightings

#whale watching cruise

#coworking space Jayanagar

#Hot deskspace Jayanagar

#board Room Jayanagar

#drrajdahiya

#drrajdahiyamd

#prostatecancer

#radiationtherapy

#Content Marketing Agency

#boat charter

#booze cruise

#cocktail cruise

#happy hour cruise

#burial at sea

#carpet cleaning ipswich ma

#carpet cleaners in ipswich

#carpet cleaning salem

#peabody carpet cleaning

#best whale watching tours

#WHALE WATCHING SEASON

#BEST WHALE WATCHING

#touchscreen software

#interactive signage

#digital signage rental

#Meeting Space Jayanagar

#Discussion Space Jayanagar

#Roofing Companies

#Roofers Battle Creek

#Lp gas

#residentiaI propane gas

#how to prepare abalone

#folding patio doors

#CCTV Installation

#Website Maintenance Services

#buy seafood online

#best seafood in san diego

#IC Source

#ICSource

#Production Tool Supply

#Reliable Product Sourcing

#Product Sourcing

#Precision Measuring Tools

#fresh fish delivered to your door

#fish market in san diego

#How is Car Accident Attorneys Fort Myers a genuine consultant of legal service?

#Website Company

#drywall companies

#drywall installation

#bedroom furniture london ontari

#How is hardwood flooring contractor a highly experienced and extensively trained?

#Local Exhibits create the perfect trade show booth for your brand. We are best Booth Designers

#laser engraving

#Display Design

#And Experts Company in USA. TO know more about

#Discussion Space Jayana

#harbor cruise

#boat rides

#party cruise

#sportfishing

#fishing charters

#fishing trips

#boat tours

#magician

#Why is spring water Melbourne pure drinking water supplier?

#Manage IT Services

#Video Surveillance System Installation

#Security Camera

#Security Camera System

#CCTV Camera Installation

#storybrand marketing

#building a content strategy

#financial services marketing

#messaging strategy

#successful content marketing

#how content marketing works

#storybrand certified guide

#storybrand certified copywriter

#Corporate Event Magician

#Magician Phoenix

#Birthday Party Magician

#business process outsourcing

#nline learning

#Learning analytics

#Learning assessments

#Content development

#KPI analysis

#LMS Management

#Metaverse eLearning

#y fresh seafood online

#propanegas

#Empowerment Speakers

#Documentary Filmmakers

#Education Speakers

#Economy and Finance Speakers

#Diversity Speakers

#Current Events Speakers

#Customer Service Speakers

#Screenwriters speakers

#How are digital signage companies offering many different applications for signage?

#Buy Online Shower Screens

#Buy Designer Radiators Online

#Buy Walk-In Shower Enclosures

#Shower Enclosures With Shower Trays

#best Sewing Machines

#singer Sewing Machines

#best sewing machine for beginners

#singer sewing machine model

#singer 44s heavy duty sewing machine

#Why are Certified Speaking Professionals so much important for you?

#ledvideowall

#Football Speakers

#Foreign Policy Experts

#Futurist Speakers

#Fitness Speakers

#propane gas company newaygo county

#propane gas company allegan county

#KalamazooRoofing

#RoofingContractors

#RoofingCompanies

#BattleCreekRoofing

#RoofersBattleCreek

#HealthcareSpeakers

#HispanicHeritageSpeakers

#HockeySpeakers

#HallofFameSpeakers

#HealthAndWellnessSpeakers

#Homeandgardenpersonalities

#HomelandSecurityandTerrorismSpeakers

#cocktailcruise

#harborcruise

#boatrides

#burialatsea

#partycruise

#boattours

#boatcharter

#fishingcharters

#fishingtrips

#WHALEWATCHINGTOURS

#recentwhalesightings

#whalewatchingcruise

#bestwhalewatchingtours

#WHALEWATCHINGSEASON

#BESTWHALEWATCHING

#ahealthydivorce

#divorcemediation

#familyattorney

#filefordivorce

#mediationsandiego

#mediationcenter

#CorporateEventMagician

#MagicianPhoenix

#BirthdayPartyMagician

#localexhibits

#exhibitscompany

#tradeshowboothdesign

#tradeshowrentals

#tradeshowbooth

#exhibitdesignfirms

#buyfreshseafoodonline

#freshseaurchin

#abaloneforsale

#sashimiathome

#howtoprepareabalone

#buyseafoodonline

#bestseafoodinsandiego

#freshfishdeliveredtoyourdoor

#fishmarketinsandiego

#waterbottlewithinfuser

#reusablewaterbottleswithinfuser

#infuserwaterbottle

#waterbottlewithfruitinfuser

#clearreusablewaterbottles

#ProductionToolSupply

#ReliableProductSourcing

#ProductSourcing

#PrecisionMeasuringTools

#BuyOnlineShowerScreens

#BuyDesignerRadiatorsOnline

#BuyWalk-InShowerEnclosures

#ShowerEnclosuresWithShowerTrays

#ShowerEnclosureWithTrays

#digitalsignage

#touchscreensoftware

#interactivesignage

#digitalsignagerental

#digitalsignagecompanies

#coworkingspaceJayanagar

#HotdeskspaceJayanagar

#boardRoomJayanagar

#MeetingSpaceJayanagar

#DiscussionSpaceJayanagar

#Journalists and media personalities Speakers

#Inspirational speakers

#Jewish speaker

#Internet and News Media Speakers

#bathroomremodelsgreenvillenc

#newhomebuildergreenvillenc

#homeadditioncontractorgreenvillenc

#homesidingcompanygreenvillenc

#NoLimitContracting&Design

#windowreplacementcompanygreenvillenc

#greenvillenckitchenremodelingcompany

#MediaExperts

#Medical professionals

#Mental Health Speakers

#Military Speakers

#Motivational Speakers

#CruiseSanDiego

Let's talk!

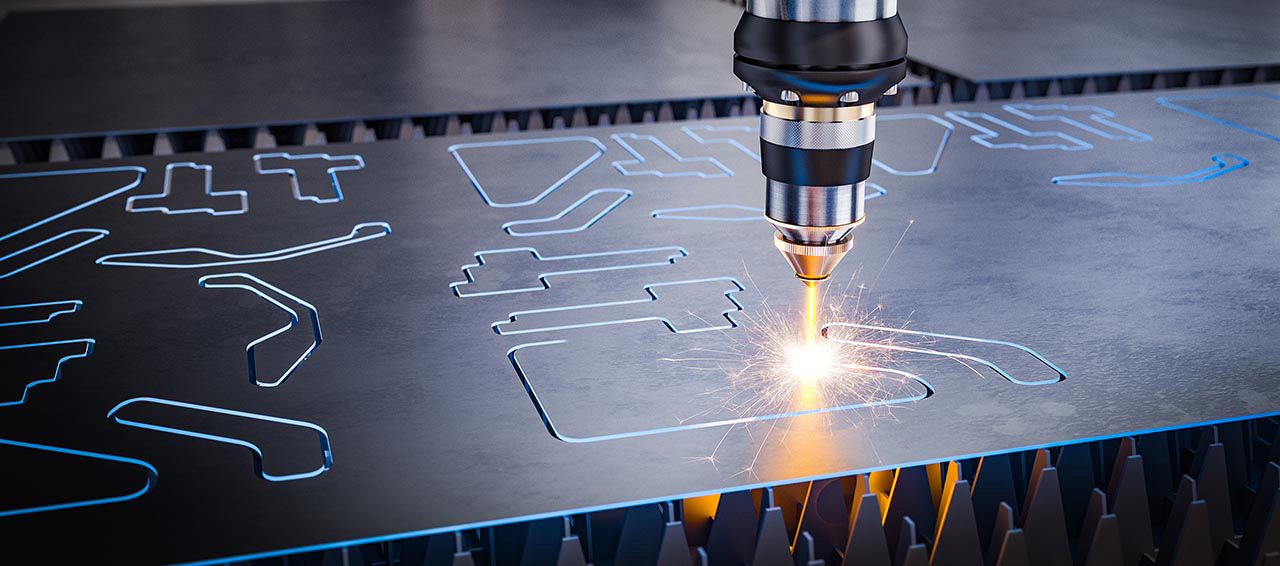

How are laser welding services the latest way of laser welding

-

Posted by rose henrry Filed in Aliens & UFO #laser cutting services #laser cutting near me #laser marking engraving #lasercut services #helium leak testing #laser engraving 2 views

Rache Corp helps associations in the USA by making ideal laser cut or engraved plans and is delighted to give laser cutting and scratching affiliations. The best laser cutting affiliations are astoundingly sorted out for principal parts for laser cutting, laser drawing, and careful CNC machining. In addition, we offer our clients unlimited customization and personalization choices. Once more, we utilize current laser improvement structures that benefit our clients.Producers can accomplish many advantages with a laser taking a gander at the cycle, be it a real particular confirmation of elements and checking or complete following for following subtleties from the assistance to the grave. The laser marks are inconceivably versatile cycles; they cover different procedures like cutting, scratching, foaming, carbon advancement, and so on. laser marking services offers a strong reaction for laser venturing, meets rules, and adds a parcel to things and parts.

The laser mark structures are utilized for everyday errands, like welding, cutting, cleaning, surveying, entering, and sense and for. Laser venturing uses a shone light release to leave durable etchings on an objective's part surfaces. Moreover, the engaged shaft revolves around a particular locale, permitting the laser marker machine to convey careful, top-type, critical difference impacts effectively investigated or reviewed across any surface.

The laser welding services, the key considerations in choosing an appropriate laser source

The laser welding services eliminate the requirement for set screws or pastes and fabricate an extremely durable bond that doesn't debilitate over the long haul. Moreover, because weld particles are more modest, the mutilation is improved, permitting more slender measures while wiping out the pre-weld treatment. Welds made with lasers can be significant, tight, minor, or fragile, and mutilation is seldom, if at any point, an issue. In pinhole welding, welds are more critical than wide, the converse of the conduction welding of lasers.

The laser shaft welding uses a focused light flood to relax metal. Since laser welding utilizes a laser shaft, no filtration materials are added with laser welding. Considering everything, they are thinking about everything. Laser welding uses laser support obsession to join the district at the apparent edges of a segment to influence changes and break something like two pieces of metal.

Precision laser welding is used in the business since it can rapidly convey quality results. Lasers can cut various materials and are continually utilized on a few select metals: carbon steel, mild steel, treated steel, aluminum composites, carbon steel, and spread-out steel. While working with high-precision laser welding structures, you can perform endeavors like joining minor metals and ensuring solid advancement since the proposing clear is pointless to indent welding results.

Precision laser welding is utilized for better jointing and fixes of advanced materials.

Laser welding for exactness welding of parts uses a related laser shaft from a flood of the poorly designed essential region for monochromatic photons as a vital connection spot for welding. High-precision laser welding structures are persistently utilized in applications requiring sheet metal creation and in auto and flying endeavors. The laser welding of the right parts can be applied to various metals, especially for welding some endeavoring to weld enlivening metals.

The helium spill testing affiliations are depicted as seeing openings in different shut or fixed structures, including helium as a "tracer" gas. Its fixation is outlined as it spills, considering a break. The helium leak testing services organizations are performed using a mass spectrometer acquainted with the presence of helium particles.

You can try a past outrageous break test to guarantee no extraordinary space, trailed by a high vacuum helium spill test in a shut chamber utilizing a helium mass spectrometer. We perform vacuum spill testing on a few of our vast parts using helium mass spectrometers. While different plans see spills, helium vacuum tests give watchful contemplations over the standard, flighty openings, and little breaks.