Recent Videos

Let's talk!

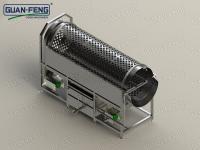

Vegetable Processing Machine To Share The Precautions For The U

-

The pure hot air produced by the hot air oven of the vegetable dryer is controlled by the hot air temperature of 50°C-160°C. The drying and dehydration methods of heating drying and ventilation drying are carried out at the same time, the hot air ventilation volume is adjusted reasonably, and the multi-layer drying box is turned over. Dry layer by layer, make full use of hot air, dry and dehydrate quickly, and run. The following Vegetable Processing Machine shares the application of vegetable drying equipment

- Vegetable dryer: If the conditions permit, it can be equipped with a spraying device to make the wood reach the effect of steaming. The moisture of the wood is discharged from the inside to the outside. The dried wood will not be deformed or inside. Crack, end crack, and other phenomena.

- The vegetable dryer can increase the hot air recovery system, recycle the hot air discharged, accelerate the running speed of the airflow in the drying room, and accelerate the drying time to improve the utilization of heat energy.

- Vegetable drying machine wood drying is not the speed of the desire, so the temperature cannot be too fast, otherwise there will be cracking of the wood, there is to pay attention to the pile of wood, pay attention to even heat, but also consider The direction of the wind flow allows hot air to circulate from the piled wood.

- Using the vegetable dryer, it can be dried to any required moisture content, which is not limited by natural conditions; It has more mature drying theory and process technology to ensure the drying quality; compared with air drying, the drying cycle is short, production High efficiency, small footprint; less complicated equipment, long service life, safe and reliable, and good economic results.